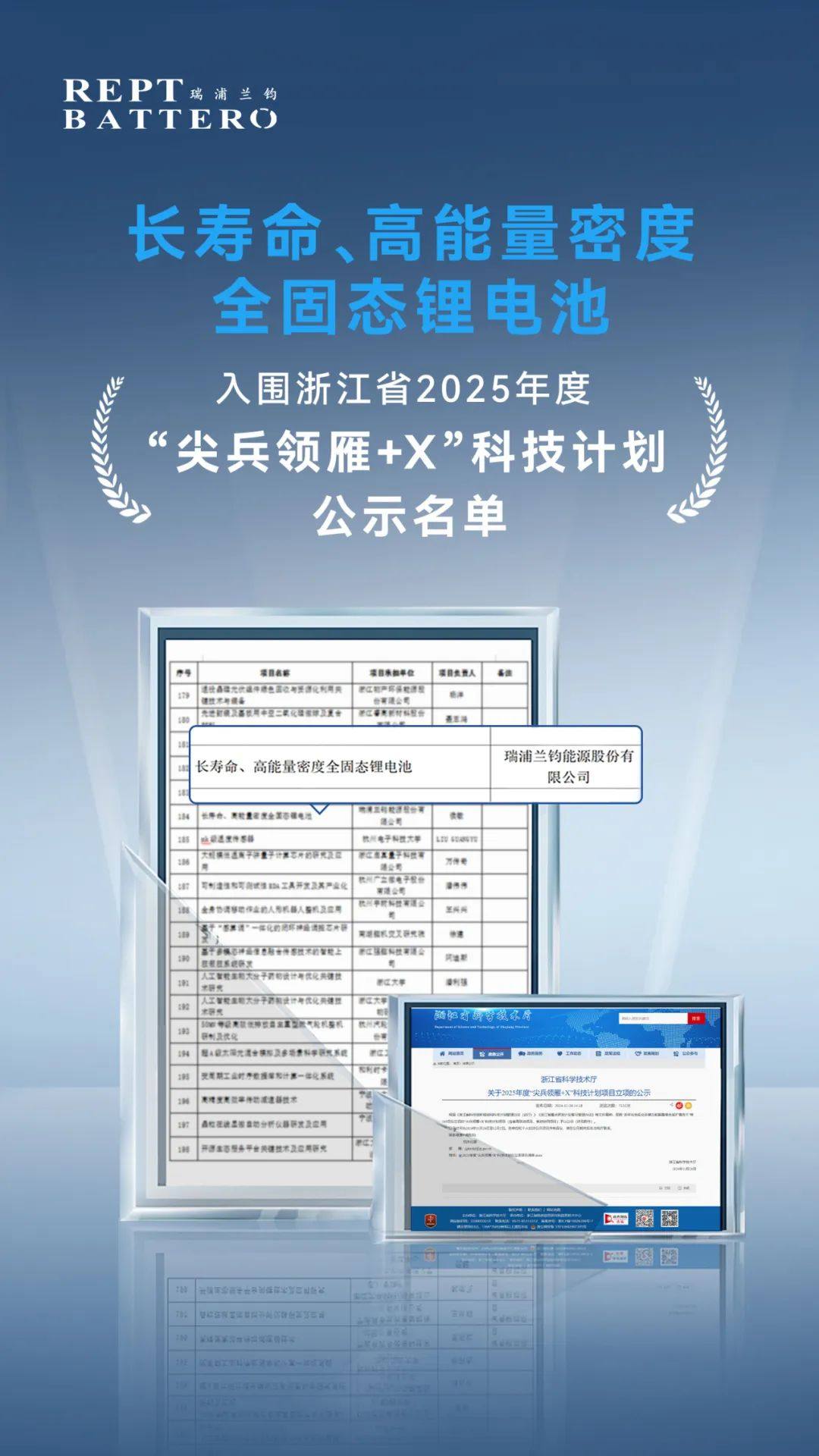

瑞浦兰钧作为牵头单位申报的“长寿命、高能量密度全固态锂电池”项目成功入围浙江省2025年度“尖兵领雁+X”科技计划公示名单,该项目将推动公司全固态电池研发进一步提速和深化。

自公司成立以来,瑞浦兰钧持续强化创新基因,打造问顶®电池技术,打破传统方形电池结构桎梏,全面提升能量密度、能量效率以及安全性能。

公司积极部署前瞻固态电池技术,在保持原有产品稳定生产的基础上,深耕新化学体系升级迭代和创新,引领技术发展热点,采用半固态和全固态两条技术路线来兼容不同的市场需求。

在半固态电池领域,瑞浦兰钧已相继开发半固态凝胶电解质、相关固态包覆正负极材料、固态电解质复合应用、相关封装工艺等,基于高镍和高硅碳体系研发了新一代的半固态电芯,方形电芯质量能量密度达到300-350Wh/kg,与国内外主流车企实现合作开发和送样测试。

在全固态电池领域,瑞浦兰钧已开展系统性前期研发并取得系列成果,通过“尖兵领雁+X”科技项目的实施,瑞浦兰钧基于材料基础研究,全面提升固态电解质电导率和稳定性,围绕固态电解质开发、固-固界面稳定性、制造工艺等课题展开微观界面表征和生产可靠性研究。通过该项目,公司制作的全固态电芯能量密度预计超过400Wh/kg以上,产品将广泛应用于乘用车以及低空飞行器等新型应用领域。

REPT BATTERO Solid State Battery Project Selected for Zhejiang Province's ‘Pioneer+ X’ Science and Technology Programme Announcement

Scroll up to read

Guided by the national dual-carbon strategy and new quality productivity, the lithium battery industry is moving towards safer and more efficient high-quality development while achieving rapid development, and all-solid-state battery technology has become the focus of industrial research.

REPT BATTERO as the lead unit declared the ‘long-life, high energy density all-solid-state lithium battery’ project has been successfully shortlisted in the public notice list of ‘Pioneer + X’ Science and Technology Programme of Zhejiang Province in 2025, which will promote the company's research and development of all-solid-state battery to further speed up and deepen. The project will promote the company's all-solid-state battery research and development to further speed up and deepen.

Since the establishment of the company, REPT BATTERO has continued to strengthen its innovation gene, and create Wending® battery technology, which breaks the shackles of the traditional square battery structure, and comprehensively improves energy density, energy efficiency and safety performance.

The company actively deploys forward-looking solid-state battery technology, and on the basis of maintaining the stable production of the original products, we are deeply engaged in the upgrading and innovation of the new chemical system, leading the hotspot of technological development, and adopting two technology routes, semi-solid and full-solid, to be compatible with different market demands.

In the field of semi-solid batteries, REPT BATTERO has successively developed semi-solid gel electrolyte, related solid-state capped anode and cathode materials, solid-state electrolyte composite application, related encapsulation process, etc., and researched and developed a new generation of semi-solid batteries based on the high-nickel and high-SiC systems, with the mass energy density of the square batteries reaching 300-350Wh/kg, which has been co-developed with domestic and foreign mainstream automobile enterprises and sent to the test samples.

In the field of all-solid-state batteries, REPT BATTERO has carried out systematic preliminary research and development and achieved a series of results. Through the implementation of the “Pioneer + X” science and technology project, REPT BATTERO has comprehensively improved the conductivity and stability of solid-state electrolytes based on basic research on materials, and has conducted research on the topics of development of solid-state electrolytes, stability of the solid-solid interface, and manufacturing process. We have launched micro-interface characterization and production reliability research. Through this project, the company's solid-state cell energy density is expected to exceed 400 Wh/kg, and the products will be widely used in new application areas such as passenger cars and low-altitude eVTOL.

The all-solid-state lithium battery is a key part of REPT BATTERO's future technological layout, and REPT BATTERO's firm and continuous forward-looking layout will promote the rapid development of related technologies and industrial realisation, and contribute to the national dual-carbon strategy with new quality productivity, injecting new vitality for the transformation of global green energy and sustainable development.

原文始发于微信公众号(瑞浦兰钧能源):瑞浦兰钧固态电池项目入围浙江省“尖兵领雁+X”科技计划公示 半固态电池已装车测试

新能源汽车的快速发展带动了动力电池的高速增长。动力电池生产流程一般可以分为前段、中段和后段三个部分。其中,前段工序包括配料、搅拌、涂布、辊压、分切等,中段工序包括卷绕/叠片、封装、烘干、注液、封口、清洗等,后段主要为化成、分容、PACK等。材料方面主要有正负极材料,隔膜,电解液,集流体,电池包相关的结构胶,缓存,阻燃,隔热,外壳结构材料等材料。 为了更好促进行业人士交流,艾邦搭建有锂电池产业链上下游交流平台,覆盖全产业链,从主机厂,到电池包厂商,正负极材料,隔膜,铝塑膜等企业以及各个工艺过程中的设备厂商,欢迎申请加入。

长按识别二维码关注公众号,点击下方菜单栏左侧“微信群”,申请加入群聊