近年来,曼恩斯特基于涂布技术的平台化特征及工艺引领装备的成熟机制,依托多年沉淀的智能制造技术,目前涂布产品已涵盖GW、中试以及实验室的单结、叠层涂布设备,可以根据不同客户的要求快速响应,提供手套箱、自动化等定制化涂布整线技术解决方案,将加快涂布关键装备的国产替代进程。

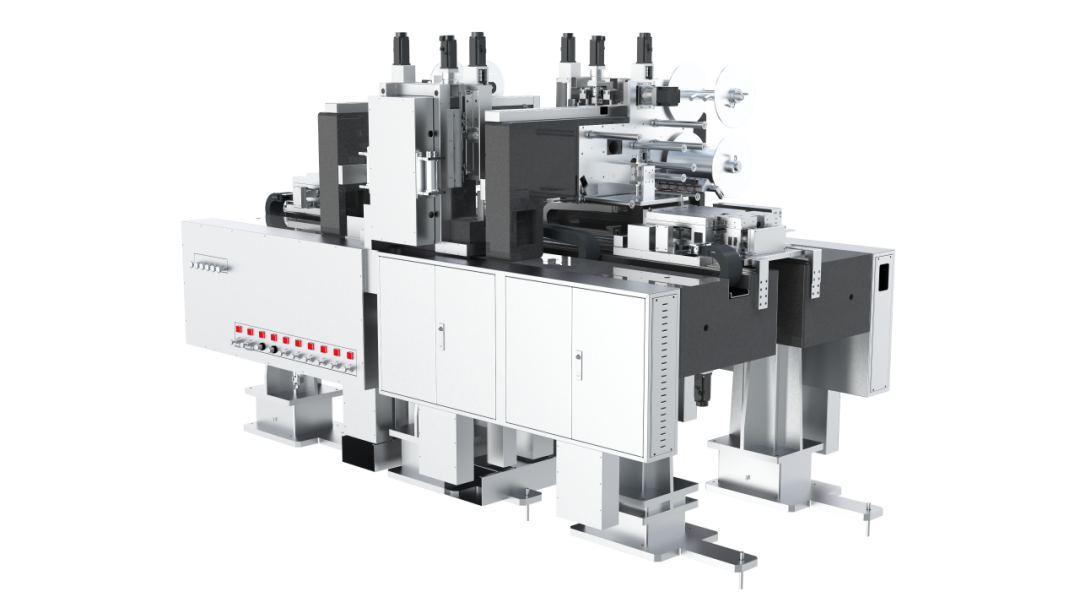

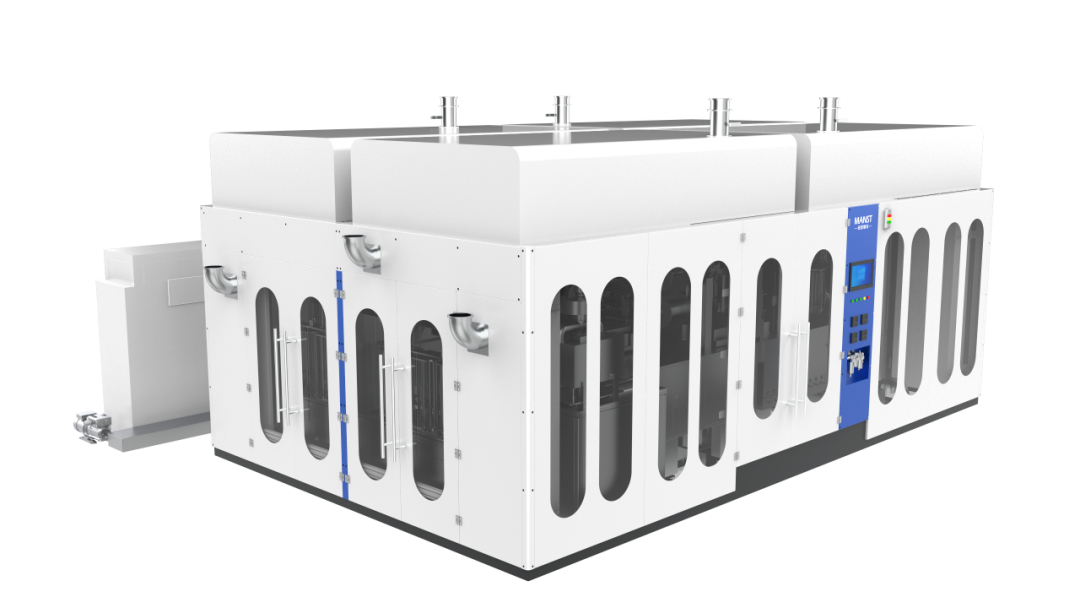

本文将介绍最新推出的钙钛矿叠层实验室型平板涂布机、钙钛矿叠层量产型平板涂布机、高通量钙钛矿叠层涂布机、200×200桌面涂布机四款设备。

In recent years, MANST, based on the platform characteristics of coating technology and the mature mechanism of process-leading equipment, has leveraged its years of experience in intelligent manufacturing technology. Currently, its coating products cover GW,mini pilot, and laboratory-scale single-junction and tandem coating equipment. The company can quickly respond to different customer requirements, offering customized coating line solutions, including glove boxes and automation, to accelerate the domestic replacement process of key coating equipment. This article introduces the latest four pieces of equipment: the Experimental Planar Coater for Perovskite Tandem Solar Cells, Mass Production Planar Coater for Perovskite Tandem Solar Cells, High Throughput Coater for Perovskite Tandem Solar Cells, and the 200*200 Desktop Coater.

涂布机产品特点:/ Features of the Coating Machine 配备全自动检测-调平-减震机构

领先的自动化上下料控制系统

搭载自主研发的高精度注射泵

专利的卡盘设计,确保涂布膜层高均一性

· Equipped with a fully automated detection-leveling-damping structure. · Leading automated loading and unloading control system.

· Featuring a self-developed high-precision liquid injection pump.

· Patented fastener design ensuring high uniformity of film layers during the coating process.

涂布机产品特点:/ Features of the Coating Machine 配备全自动检测-调平-减震机构

领先的自动化上下料控制系统

搭载自主研发的高精度注射泵

专利的卡盘设计,确保涂布膜层高均一性

· Equipped with a fully automated detection-leveling-damping structure. · Leading automated loading and unloading control system.

· Featuring a self-developed high-precision liquid injection pump.

· Patented fastener design ensuring high uniformity of film layers during the coating process.

涂布机产品特点:/ Features of the Coating Machine MES联动,可远程云端控制模式

可复合多种基材

设备配有专用脱气模组降气泡对涂层影响

涂布区搭载FFU空气净化系统

· The equipment can be integrated with the MES(Manufacturing Execution System)and supports remote cloud-based control modes, providing practical, evidence-based functionality. · Duringoperation, the equipment can applya specific slurry onto the basefilm, followed by additional layers suchas releasefilms and protective films, enhancing layer functionality and performance. · The equipment' s supply cart is equipped with a degassing module, which effectively reduces air bubbles to enhance theCoating quality and reliably prevents issues such as uneven coating distribution. · The whole system is equipped with an FFU (Fan Filter Uni) air purification system to ensure the cleanliness requirements ofequipment operation and product production process.

涂布机产品特点:/ Features of the Coating Machine 尺寸小,可在手套箱内使用

性价比高

结构简单涂布性能稳定

· The com pact size of the equipment allows it to be used within a glovebox. · High cost-effectiveness. · The equipment' s simple structure minimizes the likelihood of malfunctions, thereby enhancing the stabilityof coating performance.

原文始发于微信公众号(曼恩斯特):技术领先丨曼恩斯特最新钙钛矿叠层涂布设备

新能源汽车的快速发展带动了动力电池的高速增长。动力电池生产流程一般可以分为前段、中段和后段三个部分。其中,前段工序包括配料、搅拌、涂布、辊压、分切等,中段工序包括卷绕/叠片、封装、烘干、注液、封口、清洗等,后段主要为化成、分容、PACK等。材料方面主要有正负极材料,隔膜,电解液,集流体,电池包相关的结构胶,缓存,阻燃,隔热,外壳结构材料等材料。 为了更好促进行业人士交流,艾邦搭建有锂电池产业链上下游交流平台,覆盖全产业链,从主机厂,到电池包厂商,正负极材料,隔膜,铝塑膜等企业以及各个工艺过程中的设备厂商,欢迎申请加入。

长按识别二维码关注公众号,点击下方菜单栏左侧“微信群”,申请加入群聊